Methodology

Ship in Six

When it comes to product development, it’s no secret that the only certainty is uncertainty, and change the only constant. Rather than shying away from this fundamental truth, in our years working in automation we’ve found a way to embrace it. We call it Ship in Six.

Revolutionizing Product Development

At Loupe, we know from experience it’s impossible to account for every future contingency when making new things. Doing so results in overblown but incorrect specs, unnecessarily large safety nets, and assumptive solutions that shoehorn into the original budget but offer little flexibility to innovate and pursue what better ideas may emerge.

Instead, inspired by software industry practices, we structure our product development process around iterative six-week sprints. Each sprint is a commitment to spend a fixed number of engineering hours against a flexible (but best-effort) scope.

In this way, we break down complex, long-term projects into achievable, incremental steps — often tackling the most pressing or difficult part of a project first. Each cycle produces a shippable, finished version of the product or feature in the short-term.

Why It Works

Traditional product development models are well-intended — built to address an inherent craving for certainty. But true certainty is incredibly expensive in both time and money, so Ship in Six offers the next-best thing: risk management. The six-week sprint completely changes the way we scope work, greatly reducing the cost and risk of each step.

We’ve found that six weeks is long enough to build something meaningful, but short enough that the deadline looms from day one — necessitating focus and prioritization.

A six-week timeline also means that iteration is baked into our process. Iterative projects are smaller, easier to scope, and low-risk in terms of investment. They allow us to respond to new discoveries, making it easy to pivot the project as new opportunities or challenges emerge. The result has been greater efficiency, innovation through iteration, and ultimately better products for our clients. Often the right product can be developed faster and at a lower cost than via a waterfall model.

Most importantly, it empowers us to produce something shippable in the near-immediate future.

“The six-week sprint completely changes the way we scope work, greatly reducing the cost of the first step.”

Ship in Six in Action

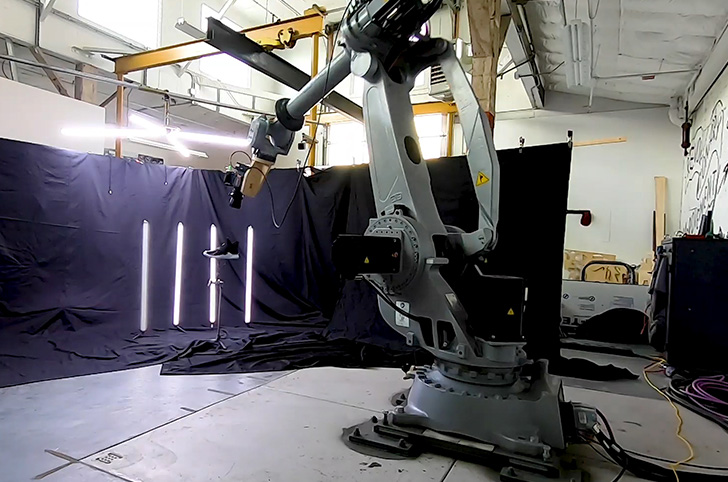

One great example of our Ship in Six methodology is our work with Swanson Studios, a still and motion photography studio.

Inspiration

Swanson often works with iconic brands to feature products like footwear or consumer electronics — using video to capture the minute details of fabric and stitching. However, this process is usually limited by the realism of CGI technology or by expensive, rigid practical rigs which can’t be easily changed on-the-go. This feels restricting, as it limits a director’s ability to respond in the moment and take advantage of creative opportunities.

Rather than scoping an entire machine to satisfy every eventual film application (setting, location, lighting, etc.), we focused on what mattered most for this project: marrying fluid, human-guided movement with the control and repeatability of robotics.

Our six-week sprint then became laser-focused on answering one fundamental question: Can we use a robot to teach human-controlled motion shots in seconds instead of minutes or hours?

Approach

With Loupe’s motion technology, we collaborated on a solution that allows a filmmaker real-time control of a robot-mounted camera — providing the fine control and perfect sweeping orbit moves of a 3D render with the flexibility of a live shoot.

Over the course of the next six weeks, we iterated and tested, fine-tuning requirements like smoothing motion to prevent the camera from shaking at start and stop. True to form, we discovered functions that became vital to the project which we could not have planned for at the outset — like combining real-time operator controls with the identical repeatability necessary for multiple takes.

Results

In just six weeks, we were able to ship a product that answered our original near-term challenge. The footage was elegantly fluid, and the detail mesmerizing. In this case, our deadline nicely aligned with a public event to celebrate Swanson Studio’s anniversary, so with a specially designed trailer, we transported and demoed the robot at the event. This was to the delight of their guests, many of whom had never touched a robot controller before.

What could we Ship in Six?

Our iterative, six-week process creates revolutionary outcomes for our clients. To learn what might be possible for your product in six weeks, let’s collaborate on a New Machine Concept sometime soon.