David Nichols on This Is Automation

Prepare yourself to be radicalized: Here’s Loupe CEO David Nichols explaining why he’s been excited to work with B&R Industrial Automation for the last 15 years. Thanks to Cory Dowless for hosting this interview on This Is Automation.

David Nichols (00:00):

Hi, this is David Nichols. I’m CEO at Loupe and to me, automation is why would we do something that a robot could do for us?

Cory (00:08):

Welcome to today’s episode of This is Automation. Today, we have a special guest remote. We have David Nichols. How’s it going David?

David Nichols (00:30):

Hello, hello.

Cory (00:32):

I guess to get us kicked off in the right direction, we can start how we always do and just David if you can, give us a quick introduction to who you are and your relationship with the B&R. I know before we hit record, you were telling me about writing [cam automats 00:00:47] in 2005 and in your apartment, so I don’t know how far back you want to go, but you apparently go back pretty far.

David Nichols (00:55):

We’ll go back all the way to the beginning. No, and not that far compared to some people that I know whose names I won’t mention. I don’t want to make them feel old, but yeah, my name is David Nichols. I’m the CEO of a company, Loupe, that’s L-O-U-P-E, like the small magnifying glass. We’re the B&R partner for a lot of the West Coast, so Northern California, Oregon, and Washington. I’ve been working with B&R as we said, for quite a while now. I initially got introduced to B&R as it was working for another automation distribution company, called PacMation.

David Nichols (01:34):

It was back in 2004 or 2005-2006. One of the products that PacMation started working with B&R and I was really interested in learning about B&R because the reason that I had gotten into automation in the first place was because I was really interested in software, I was really interested in what computers were capable of doing and scripting things and programming things. Automation was just the coolest way to do that because when you ran your code or when you hit enter, you didn’t just see a bunch of pixels fly by on your screen, but something happened in the physical world. That was what really hooked me about automation.

David Nichols (02:13):

Anyway, coming from that software background, even back then, I think we’re still proud of that, still talk about it a lot today. B&R as a software development platform, B&R as a software capability was always really distinctive and really powerful. That was what got me hooked on it even back then. That’s how I got into Automation Studio, version two point something. It’s come a long way in that time, but it’s kind of maintained the power and that’s something we’ve really taken advantage of over the years. People really appreciate when we work together.

Cory (02:46):

Nice. I wanted to talk today kind of just in general about automation. Then, a little bit about how Loupe works and some of the stuff that you guys work on because I know that there’s some neat stuff that you guys are involved in and then, just more about how you see B&R fit into the automation market and kind of what makes B&R special in your opinion. I guess before we dive too much into that, you mentioned that Loupe is a partner with B&R, so maybe you could just give us a quick intro to Loupe and your business philosophy. Yeah, just a little bit about you guys.

David Nichols (03:23):

Yeah, sure. We’ve been thinking a lot about that, I think, the core of our company and our opinions and what we’re excited about I’d say has been very consistent and reliable for the last 15 years or so, or 12 years since we founded the company in 2007, but we’ve always been engineers, so we weren’t very good at describing what that was. I’ve learned in the meantime that there are people called professional communicators, they’re called marketing people. They can take all those things that we hand wave about and are excited about and put that into words and images and ways of describing what you do that are really powerful.

David Nichols (04:05):

Our company is called Loupe. That’s a new name for a company as of about six months ago and I’d say the purpose of our company, the mission of our company, what we’re all here to do and what we’re excited about is really revolutionizing what’s going on with machines. There’s a lot of trends, there’s a lot of new possibilities, there’s a lot of changes in technology recently and over the last 200 years that we think are really awesome and positive for humanity, so we want to help push the boundaries of that and help make new things possible.

Cory (04:44):

Yeah, for sure. I think B&R has a similar mission, so I think we’re aligned very well in that way. Could you talk about what does an average customer look like for you and within that, what does an average project look like? I know I’ve seen some things on social media you guys are doing with some videographers and things like that with the robotics. Could you just talk a little bit about those?

David Nichols (05:12):

Yeah, sure. Yeah, I would say it’s not a coincidence that we work with B&R because the product and the company, we share that world view, we share those values with B&R. That’s why we started working with B&R in the first place, so that’s definitely something that we have in common that’s not an accident. I would say the similar thing about our customers, so if you look at… my description of what B&R is, going back decades now, is that B&R is a company that provides controllers and automation technology for machines where the technology of the machine is really what’s important about it. There’s different ways companies can be strong. They can be strong because they have a really powerful sales channel, really powerful marketing capabilities. When I think about a B&R customer, I think about a customer, usually an equipment builder, company that makes machines as their business, an OEM, and that company really distinguishes himself on our machines have the best technology in the world and that’s what’s great about them. That’s why people buy them, that’s why those companies are successful is by being innovative and being really capable in terms of the technology in the machines.

David Nichols (06:35):

When I think about specific examples, sort of profile what’s great in both our customers and B&R customers, they are companies that are like that and that’s because they hit throughput numbers or scalability numbers that are just untouchable. When you think about a company that makes bottling machines, you think about some of the biggest bottling machines and the biggest bottling equipment builders in the world, you think about these huge [turrets 00:07:05], they’re moving 10s of thousands of units per hour through these machines and you really need incredible technology to be able to achieve that and do it well, and do it reliably. That’s something that in a lot of cases with our customers, that’s the case as well.

David Nichols (07:24):

It doesn’t always have to be high performance, but there’s always some technology leverage that’s being put to work. We also work with companies that work in secondary packaging, which if you don’t know what that is, that’s the end of the packaging line. It tends to be slower, it’s maybe you’re stacking boxes up or maybe you’re putting things in boxes. It’s not what’s considered the complicated or high-speed part of the line. There’s still a huge opportunity for technology to have an impact in those cases and even equipment builders who make their machines completely out of bent sheet metal and stuff that would otherwise be considered dumb, you can make a great machine and bring great technology to that machine and use the benefits of the B&R platform even on these machines that otherwise people wouldn’t think of as super sophisticated or super high-end. There’s still a way to make a great machine where technology is really the key piece of it in those contexts as well.

David Nichols (08:30):

That’s what… I think maybe that’s a long answer, but that’s what I feel like is in common with the B&R customer and people that we typically work with. That’s in industries like packaging and aerospace, people that are making computer chips or equipment for making computer chips, stuff like that.

Cory (08:47):

Yeah. You mentioned at the top of the episode that Loupe is a partner for B&R and I know distribution partners is a common term in the industry, but I think the relationship that B&R has with our partners is a little bit different and the expectations may not be exactly what people think of when they hear partner. Could you talk about that a little bit and how that’s different from the rest of the market?

David Nichols (09:14):

Yeah, sure. Partner I think is a term that’s chosen because if you say distributor, people think of a warehouse where there’s a bunch of boxes on the shelves. Obviously, in the B&R channel, there are such places, but it doesn’t really encapsulate what the relationship is between both either our company, Loupe and B&R, or our two companies and our customers. I think the big difference is the sense of collaboration, the sense of we’re working together on something that if it’s successful, it’s going to help our companies grow really a lot and amazing things are going to happen. We’re bringing pieces to the table, whether that’s technology or capability or maybe there’s some programming skills or some other integration aspect where we have a contribution to make, but without people on the equipment side saying, “Hey, there’s a great opportunity here if we can figure out a packaging machine to be able to do this,” that’s something where we’re starting really from a whiteboard or we’re starting from that vision in… I guess one way to say it when we’re talking with people is, they know their industry and they know their field. They know their process so well, but we know all these aspects of technology and software and capability. When you put that together, when you can overlap that, really amazing things are possible.

David Nichols (10:39):

It goes much deeper than just a supplier or someone who you give us a purchase order and we fulfill on-time and at a good price. That’s what people think of when they think of a distribution company, but it’s really much deeper than that for us. Both with B&R and with our customers, it’s really deeply collaborative, so we’ve got to come up with different words to describe that other than distribution.

Cory (11:06):

Maybe shifting the conversation a little bit to automation in general. You’ve kind of already touched on it. It can be really technically complex. You need knowledge of both the control side and the automation side as well as that specific process and that’s where that partnership with the customers comes in. I think a lot of things are changing in the market right now as far as new technologies that are coming out. We’re making, you mentioned 200 years ago, the difference from 200 years ago to now is maybe what we’ll see from now to 20 years in the future just because of the rate at which technology is changing and the rate at which automation is being adopted. Where do you see automation making the biggest impacts right now?

David Nichols (11:53):

I think it’s a really interesting time for automation because, and what immediately pops to mind is this quote from Marc Andreessen who’s a partner at… a big venture capitalist, very successful. He also was part of the founding team at Netscape. He has this shorthand for saying, “software is eating the world,” which is a little menacing a little bit, but the fact is computing and all these aspects of technology, these are things that are changing extremely rapidly, they’re impacting the world in really incredible ways, both positive and negative. That’s filtering into the industrial worlds in some of the same ways. It has an impact literally everywhere and it I go down the list of projects and the things that we’re talking people with, you have everything from…like, I mentioned agriculture. How do we feed the entire world? Automation and robotics and software has a huge role to play in the future of that.

David Nichols (13:02):

We’re working on there’s areas of construction. Where do houses come from? Currently, they’re built by hand, by people onsite, so is that what that looks for the future? These are things that you’re talking about fundamental human needs in terms of material, providing in a material way. These are all places where automation has an impact. I think literally everywhere you look there’s some way that automation is going to be touching it. In fact, the other shorthand way to say that is if you look around you, literally every physical thing around you, there’s often a story of machines about how it got to you. Everything comes from machines.

David Nichols (13:52):

If you look at a pen on your desk or you look at your shoes, you can just imagine the army of machines that… and people as well, like no doubt about that. That’s not something that people really are typically exposed to or even think about, but it’s all around them, everywhere they go. That’s, I think, not to go super abstract on that, but machines and production technology has a huge role to play in the lives of people and alternative energy and other ways of a… it’s in everything. That’s what’s really cool about what we do. We get to get involved in all those different things and hopefully, make the world a better place by improving that.

Cory (14:42):

Yeah. It’s probably no surprise to anybody listening, but I know I think before I was working with B&R and really understood how even OEM’s, that there even were companies making machines. I think my preconceived notion is, okay, Coca Cola makes Coke, so they make the bottles and the caps and the labels and they put it all together and they make Coke. Right?

David Nichols (15:07):

I had the same set of assumptions. Yeah. It’s not like you really think about it. It’s just like, I go to the store and there’s Coke there. I don’t even think about where it comes from.

Cory (15:17):

Yeah, so this is… I think working with OEM customer and even the manufacturing facilities directly has given me a really unique, and maybe different perspective, on just like the global supply chain, like you’re saying. You look at a pen on your desk and there’s probably a machine that does the injection molded plastic parts and there’s a machine that does the mixing for the inks. There’s some metal forming machine that does the clip, so on and so forth. There’s so much involved in the supply chain of that is just beautiful in way, I think.

David Nichols (15:54):

It’s invisible to most people. In fact, the cocktail party answer of, so what do you do, I mean, normally I would just say robots, basically. That’s not exactly the case always, but sometimes I would say, “There’s these big buildings where everything comes from called factories.” [crosstalk 00:16:17] let’s start there. Inside the factory there’s a lot of machine… I would have the same expression where you don’t necessarily think, yeah, Coke would be a good example. Coke doesn’t make bottling machines; Coke doesn’t make the machines that make the plastic that makes the mold. There’s a whole world of machines behind that. If you look at something like an iPhone, it’s even more… and you just sort of fly through that thing in your mind and think of all the little chips and all the circuit boards and all the plastics and materials, all those things come from lots and lots of machines. It just is not something that most people typically have direct experience with, but it’s fun to work on.

Cory (17:02):

Yeah, for sure. It’s exciting the range of opportunities that we get to be involved with, the different markets, but working with these OEM customers, what are you seeing them driving for on their next-generation machines. Obviously, that trickles up from the end-user, but where do you see them going in the future?

David Nichols (17:26):

My personal bias on that question about what’s the opportunity, how do you say that really succinctly to me is, is your machine made of software because a lot of machines are made out of bicycle parts and they could have been built that way a hundred years ago. That’s fine, but there are a lot of new capabilities that come from software that if you can really say, with a straight face, and that’s really what powers our machine, that’s really the material of our machines is software, that to me is something that a lot of cutting edge equipment builders are thinking about. There’s different shorthand ways of saying that.

David Nichols (18:14):

The Industry 4.0 is a branding or an umbrella term for a lot of the ways in which software can contribute to manufacturing. Thinking about smaller batch sized, thinking about how to make the equipment more flexible and instead of being purely mechanical. Those are all things that I think the leading-edge equipment builders are thinking about these days because that’s where a lot of the new opportunities are. I don’t discount any of the mechanical aspects as well because obviously, they’re so tightly coupled together, but when you can bring software into your machines, there’s a lot of capability that’s come about in the last 10, 20, 30 years where’s there’s really new opportunities. Companies that do that, I think, are in a good position to grow. The world is changing because of software.

Cory (19:19):

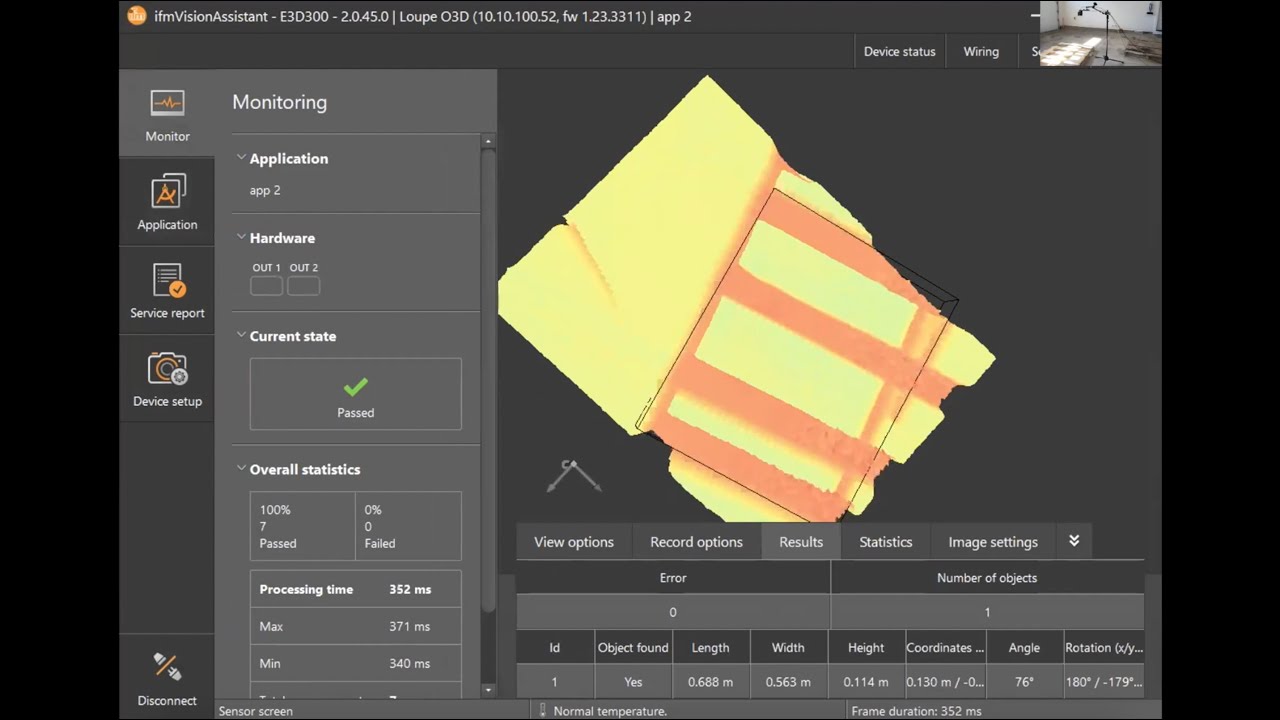

Let’s talk a little bit about robotics, which is something I know that, with the ABB acquisition, B&R is getting more involved in. I know that something that Loupe has definitely been involved in. What kind of problems are you solving with robotics that maybe you weren’t able to before and where do you see the market headed with robotics?

David Nichols (19:43):

Sure. I can tell you one of the really interesting things about robotics, and I should define what the term is. When we use the term robotics, we tend to be talking about what you would see in a car commercial where it’s a six axis arm, it’s throwing sparks everywhere because it’s welding body panels together, and if you look at the history of that type of device, that kind of robot, thousands and thousands and thousands of them have been built mostly for the automotive industry. Any of the robot suppliers, you can look at their charts and you can look at their internal marketing, that’s basically where they come from. It’s the legacy of it.

David Nichols (20:26):

They’re really good at doing that. If you need to weld sheet metal panels together, boy, there are so many great robots for you to use, but if you try to get them to do other things, there can be some limitations. They’re not that great at doing… I’m speaking broadly here, tasks that are more flexible or not quite as repeatable as go exactly to this point and pinch together and weld and then do that over and over and over again exactly the same way, but the interesting thing is, because those robots were built thousands at a time, for what they’re capable of mechanically, they tend to be really inexpensive. If you take the robot and you are able to inject a bunch of new software to give it an entirely new brain, then you can do some really powerful things because they’re basically lying around waiting to be used for that purpose.

David Nichols (21:31):

If you can augment them with other sensors, if you can make the software of them more flexible, if you can make them able to consume information from different vision systems or other sensing systems or spatial systems to make them more accurate, to make them better aligned in terms of process, to get them so that they can be more precise in time and space, there’s a lot of new things you can do with that robot besides weld autobody panels together. That’s been a big theme of our company in the last handful of years is using those robots, kind of lobotomizing them or giving them a lot of new software capabilities, so that they can be more responsive to what a machine needs to be or they can be more tightly integrated into a machine, so that they can do new things. Because of that interesting cost dynamic with them being readily available, there’s a lot of new opportunities. You find robots finding their way into all of these new applications where they weren’t used before and there’re examples in eCommerce, in agriculture, in packaging where the process flexibility and the software that you’re bringing to bear to make that robot behave, versus just run a routine, that’s something that is really cool and people that see that are people that we get excited about that. We’ve had some awesome projects and we’ve worked that.

David Nichols (23:06):

There are examples in aerospace where you take an off-the-shelf robot, put a bunch of new sensors on it, do a bunch of spatial mapping to it and all of a sudden, it can drill holes super precisely, I guess precisely enough that they can be used for airplane and aerospace manufacturing. That would be an example that you can look to and there’s some really inspiring companies that have work that they talk about publicly. Like, I’m a big fan and appreciator of what Electroimpact does and other companies like that. If you haven’t seen them do that, they’re taking these robots and using them in new contexts all the time. I don’t see that slowing down. In fact, I see that increasing over the next handful of year. We’re pretty excited to learn a lot about how to take those robots and do new things with them.

Cory (23:49):

Yep. You said something I want to circle back on about robots not being good at things that aren’t repetitive, point-to-point movements.

David Nichols (23:59):

Mm-hmm (affirmative).

Cory (24:00):

First, I wanted to ask you about, what’s your opinion on collaborative robots? Is that something… it’s one of those buzzwords. You mentioned Industry 4.0, collaborative robotics, it’s something that people get really excited about. I mean, is your opinion that collaborative robotics is a new generation of robotics or is it just another product that’s going to find its niche and it will be a part of a broader automation solution?

David Nichols (24:27):

Sure. Well, I love a good buzzword even though I also roll my eyes at them in a really hard way. It’s almost like a meme, when new things come out, people get excited about it. We’re excited about it, too. When it comes to collaborative robots, I think there’s two ways to think about that and I guess I’ll just…these are my labels. I don’t know if anybody else agrees with me, but when you talk about a collaborative robot, there’re some robots… and ABB makes robots like this, but I have to say, setting our ABB association aside, I think when people think about collaborative robots, they’re thinking about like a universal.

Cory (25:09):

Yep, right.

David Nichols (25:10):

A robot that has a low enough payload, it can’t necessarily hurt you, if it bumps into you it will stop, and you can teach it in these very human ways. When you go and read about how new technologies come to take over the whole world, a lot of times it looks like that because it’s a toy and it’s payload is really low and it can hardly do what my robot does. Anytime you hear that, you should be very afraid because that’s where technologies come from that end up going up that curve and becoming really powerful. I expect that to be the case for robots that look like that.

David Nichols (25:49):

ABB has a product called a YuMi. It’s very similar, so we definitely look at tech companies like Universal and say, “Yeah, you’re definitely onto something here. This is latched on to something that’s inspiring a lot of people,” so I’m a huge supporter of that. Love that. We’re friends with the Universal distributor here, out on the West Coast, but I think all that, comma, but I think we’re also coming from a background on the control side where building advanced safety capabilities into industrial machines is something we’re very comfortable with. B&R as a platform, has been really a pioneer of… I would say for a long time. Like, five or 10 years ago, we would talk about, hey, you can build a programmable safety system and you can build some really interesting powerful technology for getting operators deeper into your machines, for getting operators able to interact with your machines without hitting any… keeping the throughput’s extremely high. Right?

Cory (26:57):

Mm-hmm (affirmative).

David Nichols (26:57):

Making so that someone can walk through an entire cell and the safety system is aware of where they are and can either stop different pieces of equipment of move different parts of the machine at safe enough speeds where a person can get out of the way in a certified way, in a legitimately safe way. That’s something that we’re very comfortable with coming from the PLC and safety control side.

David Nichols (27:21):

To put that together with a product like… that would normally be considered a conventional robot. It has a huge payload, it has a huge reach, it’s the robot exactly that you’re thinking of that’s shooting sparks and welding car bodies together. In our mind, there’s no reason that robot can’t be collaborative as well because if you augment it with safety systems, if you’re using the area scanners, if you’re using maps and there’s ways to safely establish where humans are and have them being interacting with machines in a way that’s very, very flexible. We have a robot in the middle of our workspace in Portland that it doesn’t have cages built around it. It just has area scanners, so if a human or if anything comes in with range where the robot could reach it, the robot is certified to run below a safe speed. That’s enough to make the robot collaborative, even though it can move at four meters per second, even though it can swing a payload of 40 kilograms around.

David Nichols (28:21):

I feel like there’s a lot of opportunities there where that heavy industrial, that high throughput, super-high speed, can be made collaborative and that’s where a lot of our attention is going right now because of the software and the safety capability is there to do it. There’s no reason why this robot that can swing 500 pounds around shouldn’t be able to have an operator walk up right next to it and not be scared or not be in danger. When you can do that, I feel like it opens up a lot of new possibilities for cell layouts, for productivity, for ways of controlling robots where the humans are right up next to it. They’re head’s right down next to the tool point and that’s safe.

David Nichols (29:04):

We’re really excited about that capability because it’s putting together high-performance, high-throughput, high-speed, high-payload together, but operating in a safe way very close to humans. There’s a lot of interesting technology that’s coming out that’s in support of that trend as well.

Cory (29:20):

I’m jumping back now to my point about robots not being good at non-repetitive tasks. Do you see that changing at all with machine learning and AI starting to find its way into industrial applications or have you thought about that yet?

David Nichols (29:37):

Absolutely. I think the analogy that I would sometimes use is, if the process is like a… This might age me or put me within a certain range, but I just imagine like a cassette tape and if you hit play on the cassette tape, and that basically could describe your robot process, you’re probably missing some opportunities for flexibility. You’re probably missing some opportunities to be making decisions, defining behaviors, responding to what’s actually happening with the cell or with the product or with the variability in what you’re do… if a cassette tape could work, then you’re missing something.

Cory (30:20):

Right.

David Nichols (30:21):

Or there could be more opportunities. Even car body welding, different cars are coming down the line these days from car to car. That’s not even enough anymore for I think those kind of contexts. Yeah, making machines that are capable of consuming information from other systems, that could be a machine learning system, that could be a vision system, that could be a system that’s looking at a stack of boxes and saying, “Where are the division between the boxes because this pallet is completely random and I need to be able to unpack it.” Right? All of those, the way that a robot moves, the way that a robot plans and makes decision in terms of I’m going to pick up this and then I’m going to pick up this, then I’m going to pick up this.

David Nichols (31:04):

Those are all really valuable problems to figure out, but the cool thing, like I mentioned earlier at the start of the conversation was, there’s physical limitations in the world, so how a robot moves, where a robot moves, if you don’t know that ahead of time, it can be tricky. There are these mathematical things called singularities. You don’t want to be running your robot through them, so how do you avoid them? What do you so that if it tells you to pick up a box, what will be the center of the singularity point you probably don’t want to do that? Having that flexibility, it can be tricky. What’s really interesting and what we get really excited about is the degree to which all this technology that’s being developed, it really does all plug together. Whether you’re making machines, or we’re in the context where we are making machines, and the machines are made of computers. Well, computers can also run technology that has been developed for video games, computers can also run user interface technology that comes from websites. These are both areas where just billions and billions of dollars have been spent on making the coolest stuff possible. There’s no reason why it can’t be used in machines. It all plugs together because everything is made of computers now.

David Nichols (32:28):

That’s what’s really exciting is to kind of look in our peripheral vision and finding something from a different space or bring it across from a place where it’s considered to be normal or taken for granted even. That is really powerful and there are development techniques, there are software tools, there are a lot of things that I think would be taken for granted, or not even considered state of the art, in the world of software where if you can get them across that chasm, if you can get them across that bridge to industrial space, you can have a huge impact.

Cory (33:01):

A question I get a lot is why would I use B&R instead of X, Y, or Z controller? What’s your answer to that question?

David Nichols (33:09):

My answer to that question is everything that I’ve said so far. If you’re going to use a B&R controller exactly the same way that you would use a different platform that didn’t have as distinguished technology and capability and performance, and that’s the only thing you’re changing, yeah. First of all, I’m sure we could be more cost-effective for one thing, but that’s usually not enough to justify in those cases. If someone’s unsure about that, it’s because the foundation of the question is, I don’t understand how this is different. I don’t understand what I would stand to benefit from using something different and oftentimes, at that stage of the conversation, it’s just hard to get that across. I think that they can be very distinctive. I think there can be very good reasons and there are important differences.

Cory (34:01):

What would you say you’re favorite thing about B&R as a company is, or maybe like your favorite product? What’s something that really gets you excited?

David Nichols (34:09):

What gets me excited about B&R is the pattern that… the stuff that we work with is really ahead of the industry and it’s been that way for a really long time. If you want to see what a lot of big brands will be touting five years from now, you can just look at what B&R is doing right now. If you go back through the history, one example that I know that… it changes. It changes over time. A couple examples that come to mind are… this is before my time, but B&R came out with a digital network [servo 00:34:50] drive that was running on ethernet. No one was doing that. That was totally revolutionary. Now, if you look at that, of course, that’s how everything works now. If you look at safety, if you look at the entire idea of having an integrated tool that combines a PLC and an HMI and a motion controller and a safety controller, that’s something that a lot of companies nowadays will try to say that they have and maybe we can argue about… well, they’re not quite doing it exactly right, but they say that now.

David Nichols (35:24):

There was a time 10 years ago where that was unheard of and you could go into a meeting and say, “Hey, see, it does all these things together. You don’t have to spend all your engineering time just getting these four devices to coordinate with each other. You can actually make your machine… you can spend that time making your machine a better machine.” That was amazing. Now, everybody talks about it that way and if you look at stuff that B&R is doing with track technology and some of these new concepts that they’re coming up with, the hardest part of that actually is being on that cutting edge is a lot of times people will look at and say, “I don’t get it.” Say, “Well, just let it sink in for five years and then everybody will be talking about it.”

David Nichols (36:09):

Then, again, bad on us maybe for not being able to help people see it sooner, but I know that if I keep working with B&R, I know that if I make an investment in the B&R platform, as I have founding a company and working with B&R for 15 years, that it’s not just a one-off thing, hey I love this product. Well, a lot of people will have that product or that won’t be such a big deal five or 10 years from now, but to work with a company that’s constantly coming out with new technology that is revolutionary is really, really cool.

David Nichols (36:46):

If you’re getting bored with what you have or you feel like competitors are catching up, well, just… there’s probably something in the pipeline at B&R that’s coming out next, that is going to be revolutionary as well and that’s something that a lot of people that have worked at B&R for a long time really do appreciate and it’s relevant to their machines, it comes from that collaboration with their clients and really responding to those needs. It’s a big-picture thing, but that’s what’s really cool about it and you can go down this long timeline of revolutionary things that B&R does. That’s because that’s what’s at their core, that’s what the core of B&R is, is the ability to do that. That’s really special.

Cory (37:24):

Talking about Loupe, then, what excites you about what you guys are doing right now and where you’re headed in the future?

David Nichols (37:31):

What excited me about what we’re doing now is that it doesn’t… a lot of days it doesn’t feel like work because it’s like playing with toys. There are so many fun things to put together and new ideas to come up with and sometimes, your ideas turn out to be not that great after all, but there’s so many possibilities to experiment with. The one’s that make it through are the ones that do turn out to be really powerful. They end up helping the company grow; they end up making our company very successful. There’s just many possibilities that it’s just the harder part is just not getting too carried away or finding a way to build a company sustainably while doing that at the same time. To me, it’s like, there’s so much cool stuff to play with. I say play intentionally because it doesn’t feel like work a lot of time.

Cory (38:29):

Something else that I noticed that you guys do a lot of is you have a really… I assume you have a really strong marketing team. I see your videos pop up on LinkedIn and I’m sure anybody who goes to take a look at you guys can really get a feel that branding and marketing is important to you. Why is that important and why is that such a part of your culture?

David Nichols (38:53):

Well, thank you and I said it earlier in the conversation that I feel like the core of our company has been that for a long time. What it’s taken us more than decade to learn how to do is to have that, capture that, and have it look that way from the outside because if you go back in our history, we’re excited about the same things, we had a lot of the same processes, a lot of the same ideas have been there for the longest time about how should you run your company, what’s the right fit kind of customer, what are the cool opportunities? These are all things that have been steady, but we haven’t been that good at expressing ourselves because we are engineers. We’re people that make machines, we’re not marketing people. We don’t know how to capture that in a brand.

David Nichols (39:43):

In the last couple years, it was really a couple years ago where in trying to grow the company and, to be honest, in my opinion failing to really connect with people. We would go into a meeting and we might talk excitedly for an hour or two. Then, we would come out and people would say, “I have no idea what they were just talking about because they seem excited, but I don’t get it.” What I learned was, by collaborating with people who are marketing experts is there are ways… there’s effective ways to collaborate with people who can help you put what you’re excited about into words. Help you put what you’re excited about into images, help you put what you’re excited about into video. I’ve learned and I’ve stolen so many ideas from people who are good at those aspects and brought them into the company because we think what we’re doing is really important, we’re really excited about it, and we need to learn how to express it in all those ways.

David Nichols (40:43):

If we do that, if we’re successful at that, then people who relate to that or people who are saying… people, our peers, or people who have a kinship on those kind of values, or whether that’s a customer or a supplier or a potential employee, people that see that and relate to it and are also excited about it, are going to appear as if by magic. It’s really, really cool when people say that. Again, I don’t assume that what we do is going to be appealing to everybody. What’s important to me is it’s appealing to the people who we want to work with, the people who would be great customers for us, who we’d have great relationships with. Figuring out how to blast that out into the world is something that’s been a key effort for the last couple of years.

Cory (41:32):

A question that some of the listeners may have. I know it’s something that’s been bouncing around in my head. What’s inspired you to start your own company and what was that journey like? Do you have any advice for anybody out there in the automation world or otherwise that may be considering a similar path?

David Nichols (41:52):

I should put into context what happened that resulted in this company being started, which was I mentioned I worked for an automation distributor, another company, and now I work for this company. What happened there? What happened was that company was acquired. The owner of that company sold it to a larger company and anybody who’s been involved in acquisitions knows the good and the bad and the drama that can result. I think I was 25 at the time, my co-founder, business partner still to this day, Karl Robrock, was I think 28, maybe 27. I would say two things I would give big credit to. One, having very little to lose. At that time, I was making what I was making as an application engineer and I figured, if I try this and it fails after a year, then I could probably take that experience and get a much better job than I ever had before because I would explain, “I tried to start a company and it failed and here’s what I learned. Then, hey, guess what? That was a better education than I could have gotten from business school.”

David Nichols (43:03):

Even though age is a factor, where are you in your life is a factor, I would say similarly, there can be an aspect of that whatever point in your life you are, which is I can experiment with this, I can try this, and the downside scenario, the worst case scenario is complete acceptable because, hey, I’ve kind of got nothing to lose. If you can engineer a way to make an experiment that you can run where if it doesn’t work, no big deal, that’s a good way to be because then if it keeps going, you’re like, “Hey, cool. I can keep doing it.”

David Nichols (43:44):

For the longest time I said, “We’re successful because we’re still a company.” That was because we were balancing this, yeah, we only had so much income, but we just kept it small and we grew it over time. We didn’t take any funding or any… well, I mean, with a couple friends and family kind of things, which would be typically. Again, point of privilege thanks to everybody who helped us in the beginning, but that’s something were even now we do experiments in our company and the experiments that we run, they’re not putting the company at risk, but the ones that work, are really powerful. The ones that break through, end up growing the company and being really, really important.

David Nichols (44:26):

Keeping the bets small enough to lose, is something that you can do over a long period of time. That’s why 12 years into the company, I said for the longest time we were just taking over the world slowly because we were just as long as what we’re doing, as long as we can keep making bets, as long as we can stay alive, then we can keep trying new things, making changes. Even, it’s not always the same if you’re right out of engineering school or you don’t have kids or you don’t have debt or you don’t have any of these other things that are holding you back, but I’d say at any point, with regards to your situation, there can be an opportunity to say, what experiment could I run that I could tolerate losing? If you keep doing that, you can kind of stack things up from there. That’s, if I had a business lesson, that would be it. Sometimes things really pay off and then you can grow faster. Great.

Cory (45:24):

Anything else you want to say about automation or about Loupe? Maybe plug the Loupe website where people can find out more about you guys?

David Nichols (45:33):

Absolutely. I’m very proud. I talked about some of these branding concepts in a high-level way. We just launched our new website. It’s at Loupe.team, L-O-U-P-E dot T-E-A-M, and yes, team is a high-level domain. Team is what we are, so we’re Loupe.Team. You can check out a lot of our media is there, our videos are there, you can see what our workspace is like, what our culture is like, our values. These are all things that we figured out how to talk about and we’re really proud of sharing with the world. If it sounds interesting to you, we’d love to talk to you, collaborate with you whoever you are. LinkedIn is a really big thing for us, so follow us on LinkedIn, find me on LinkedIn. Again, my name is David Nichols. Send me a LinkedIn invite and, if you don’t know me, then you send me a LinkedIn invite, then we will know each other, and I will accept it. I look forward to meeting anybody who is interested in collaborating with that.

Cory (46:30):

Awesome. Well, thanks David. I really appreciate you taking some time to chat with me and I’m sure this will be a valuable conversation for people to listen into.

David Nichols (46:42):

Likewise. Thank you very much, Cory. It’s been a lot of fun.

Cory (46:44):

In future episodes, we’re going to be diving into more exciting topics and common questions in automation. Coming up, we’ve got some episodes on machine vision, a special episode on robotics, a couple other exciting things coming down the pipeline, more special guests, special topics, etcetera. You want to make sure that you keep an eye out for those by subscribing to the podcast on Apple Podcasts, Spotify, or wherever you listen to your podcasts and if you enjoy the podcast, let us know by either sending David a LinkedIn message or leaving a review and a comment on Apple Podcast. If you want to get in touch with me, have an idea for the show, or just want to chat, you can get in touch with me on LinkedIn or email me at AutomationPodcast@gmail.com. Make sure you check out the B&R website and YouTube channel by searching B&R Automation and, of course, check out the guys at Loupe as well. They have some great content. Thanks for listening and we’ll see you next time on This is Automation.