Inspiration

The Secret Weapon Powering Elon Musk’s Revolutionary New Battery Factory

At this year’s Tesla Battery Day, Elon Musk announced a novel automation production system. Hear from our CEO and Co-Founder David Nichols as he unveils the technology behind this revolution, and the familiar process they took to get there.

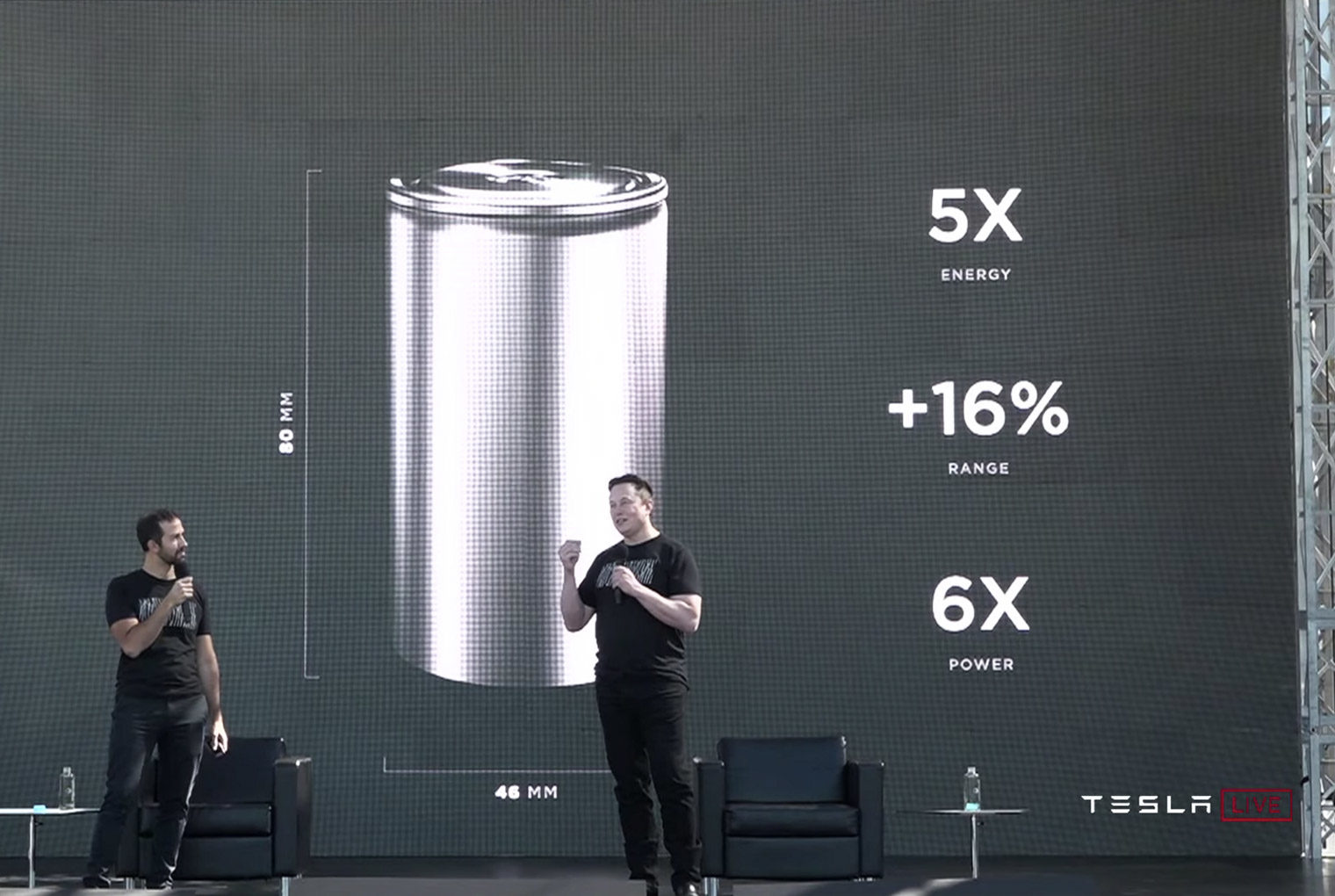

Tesla fans know that Battery Day is a big deal. Once a year, Elon and crew unveil their latest game-changing technologies to revolutionize transportation and bring about a new sustainable energy future as quickly as possible. They’re passionate about it — lives depend on it!

Normally that means a lot of talk about electric cars, which I love — but not as much as I love novel automation production systems. And leading up to the event, Elon teased that their manufacturing teams are working on something very special.

They did not disappoint. Two hours into their presentation, they pulled back the curtain on their revolutionary new battery production systems.

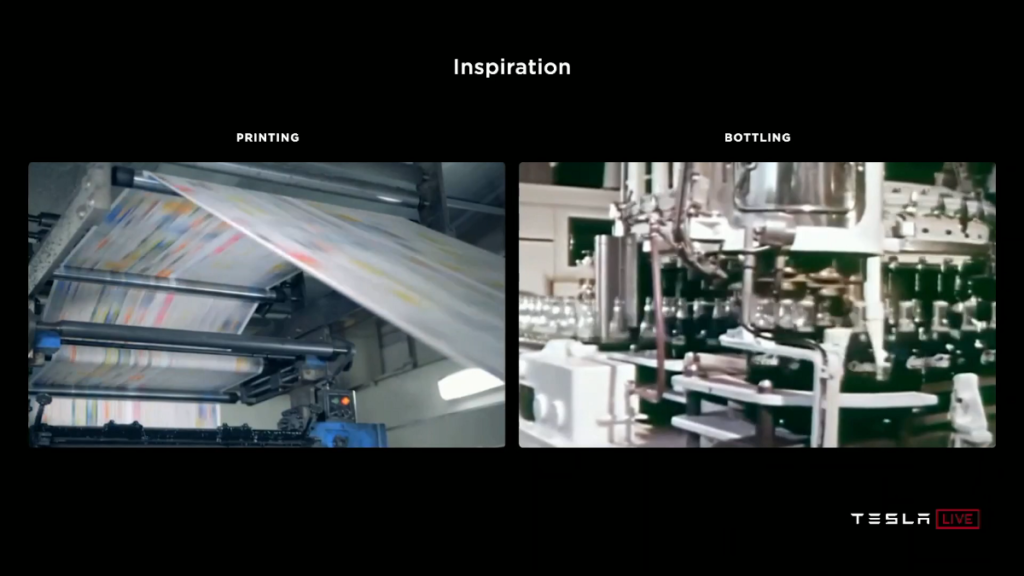

Inspiration

Just like we do at Loupe, they started with inspiration: a lightbulb moment, a cocktail napkin sketch. Naturally, the thinking behind their concept is simple, even obvious.

“When thinking about the ideal cell factory, we have inspirations behind us in the paper and bottling industry. Where from humble beginnings, over a century of innovation has enabled mass scale, continuous motion, unbelievably low manufacturing costs. … That was the inspiration that we set out to the team, as we thought about how to marry cell design and manufacturing in the best possible factory.” – Drew Baglino

High-Speed Continuous Motion Assembly

He then talks about what it means to perform production without ever stopping:

“The key to a high-performing assembly line is accomplishing processes while in motion, continuous motion, and thinking of the line as a highway, max velocity down the highway, no start and stop, no city driving.” – Drew Baglino

“No stop lights and traffic lights or anything. You want the highway.” – Elon Musk

Already they’re touting what this means for their production numbers:

“Through all of that development, we were able to get to the point where we can implement assembly lines — one line — 20GWh. Seven times increase in output per line. And when you’re thinking about scalability and pure effort, having one line be 7X the capability is just effort multiplying.” – Drew Baglino

It’s All About Speed & Density

It turns out, there’s a simple equation based on first principles to explain why revolutionary improvement is possible here. Elon gonna Elon:

“If you think about the fundamental physics of a factory … it’s basically saying, how fast are things going and what percentage of the factory volume is doing useful work. So if you break the factory down into cubic meter sections or smaller, … is a majority of this volume doing useful work? You’d be astounded at how bad most factories are. They’re maybe two or 3%, including our factory in Fremont. [Volumetric efficiency could be] more like 30%, maybe more. [That’s] 10X better, which means the factory can be 10 times smaller. And then the other thing is how fast are things going through the factory?” – Elon Musk

A factory that’s moving at say twice the speed of another factory is equivalent to two factories basically.

The Entire Factory is One Machine

Baglino breaks down their design intent behind thinking of the entire facility as a single machine with continuous flow:

“And the vertical integration with the machine design teams at Grohmann and Hibar and others allows us to really accomplish that because we don’t have any of these edge conditions between one piece of equipment and another. We can design the entire machine to be one machine and remove all of these unnecessary steps.”

– Drew Baglino

ACOPOStrak — Revolutionary Transport:

So what makes them think this is possible? And if it is, would they really have the audacity to reveal how and why in a keynote speech?

Perhaps at Tesla they’re confident enough that their design and engineering is so groundbreaking and audacious that no competitor could copy them. Or maybe they just can’t resist sharing with the world how amazing it is to see in motion.

But it’s right there hiding in plain sight: close watchers of their teaser video can spot a new shuttle system running the backbone of this facility, enabling many of the process innovations they’re bragging about:

It’s the ACOPOStrak — a revolutionary linear motor shuttle transport technology from B&R Industrial Automation.

These shuttles are the key enabling component of Elon’s alien dreadnought, seamlessly merging high-speed production systems together in a way where nothing ever needs to stop moving.

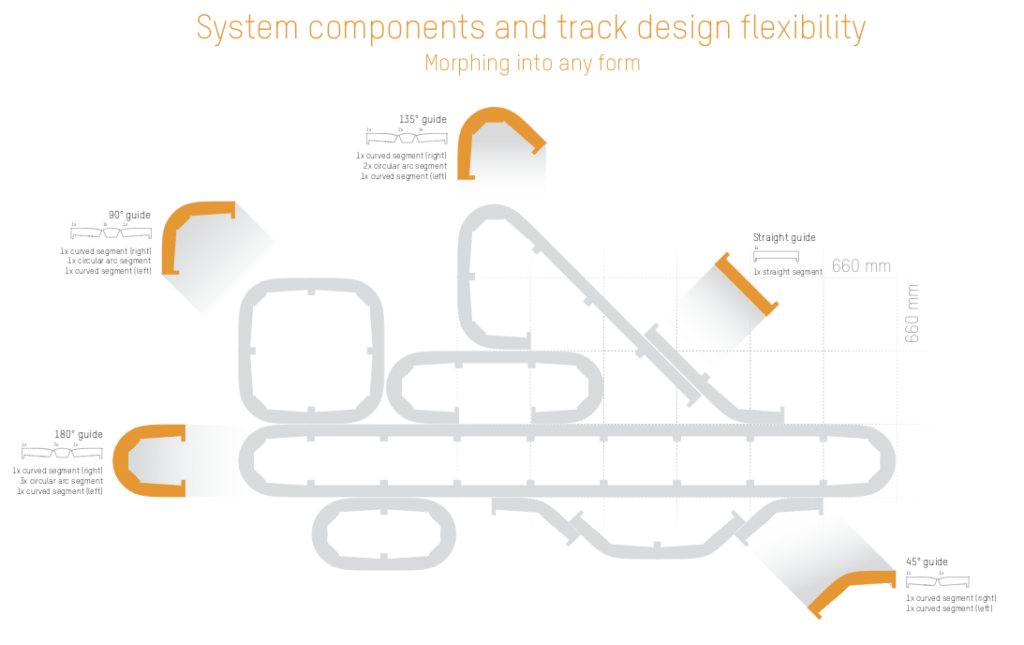

ACOPOStrak can position and synchronize each shuttle independently across huge expanses at up to 4 m/s. And the shuttles can electronically divert back and forth between track segments at those speeds, enabling branching and merging architectures of any variety:

Continuous motion process flow. Extreme speed. Order of magnitude increase in factory density. One machine.

In any other field, spending billions of dollars to yield a few percent of usable volumetric efficiency would be considered unthinkable. Why do we accept it as standard manufacturing practice?

Tesla has always been straightforward about their intentions and even the details of their plans to accomplish it. People typically scoff. But despite all the naysayers and their frequent course corrections, so far it’s been a very bad idea to bet against them.

Elon’s dead on:

[The] company that will be successful is the company that with one factory can accomplish what other companies take two or three or four factories to do.

Tesla is aiming to be the best at manufacturing of any company on earth.

Which kind of company do you want to be?

I’ll be working with companies on the winning side of this. Speed and density or bust!

PS — If you want to hear more about the revolutions underway in automation and manufacturing, follow me on LinkedIn.

PPS — You don’t have to take my word for it — watch them explain everything themselves here, starting at 1hr:15min here:

Contributor

David Nichols

CEO

CO-FOUNDER