Collaborations

A High-Stakes Prototype in Construction Automation

When a venture-backed startup needed to advance their construction technology, they turned to Ship in Six. Learn how we transformed a rough concept into a sophisticated prototype.

Our client is a venture-backed startup focused on revolutionizing the construction industry. Their first focus? An automated, cable-driven platform capable of performing complex operations across large surfaces. With a small team of 2-3 developers and limited hardware resources, they needed external expertise to advance their prototype and secure additional funding.

THE CHALLENGE

Motion Planning with Cable Control

When they reached out to Ship in Six, they had a basic prototype with a single axis but no complete robot. To move forward, they needed a more functional prototype that could demonstrate their technology to investors. However, they faced significant challenges in their control system and motion planning.

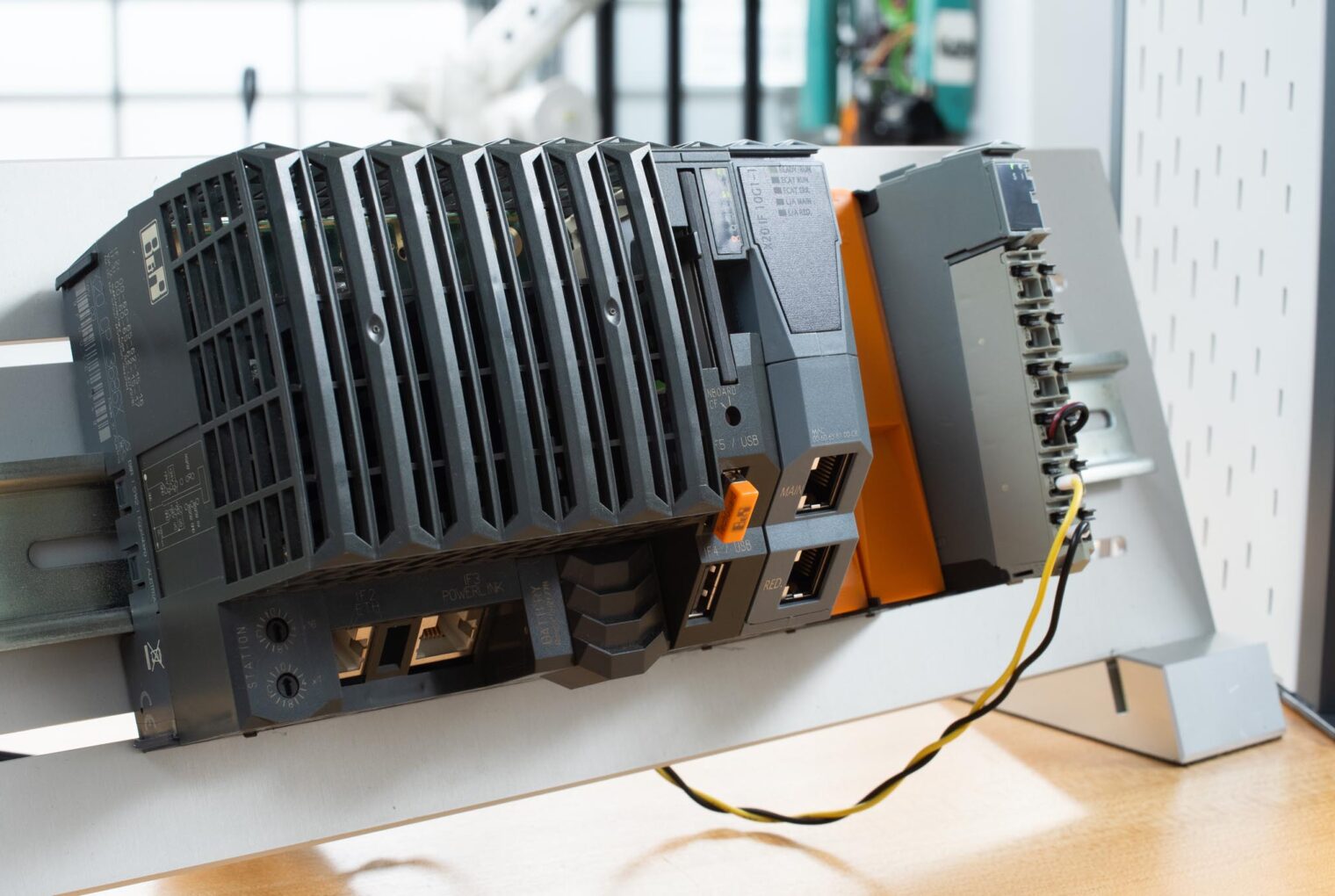

Designed for precise movement across vast surfaces, the system required five cables connected to each corner of a platform, with wheels providing additional support. This critical balance of cable tension was coordinated via control algorithms. So, they sought our help in developing a software stack that could manage this motion planning and control system for smooth and accurate movements.

THE SOLUTION

Balancing Simplicity and Precision

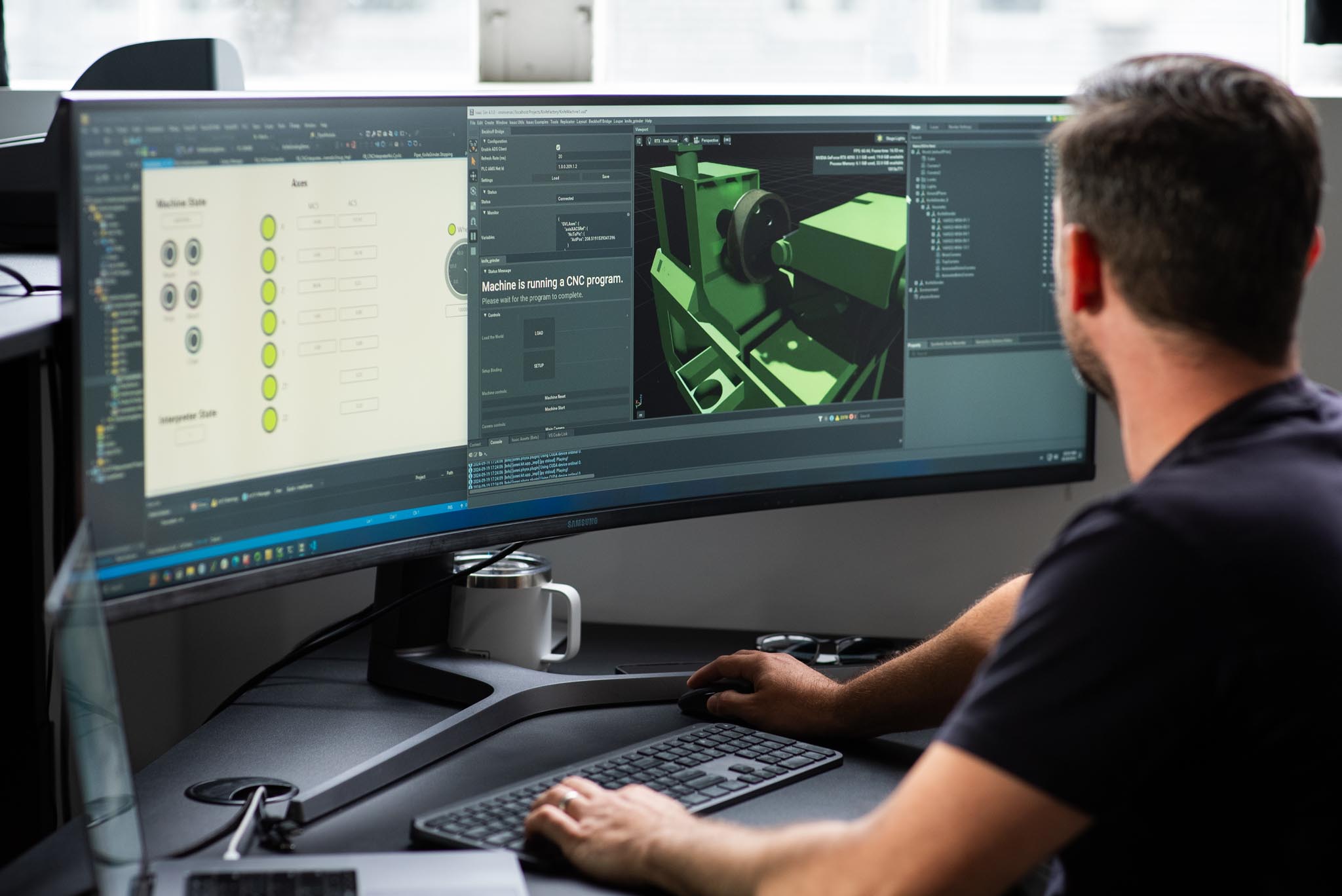

The company’s initial approach involved trying to model the dynamics of the robot, but this proved to be highly complex and error-prone. Instead, we proposed a different control scheme: using tension control for some cables and position control for others. This hybrid approach allowed the system to auto-equalize tension, leading to more reliable and consistent movements.

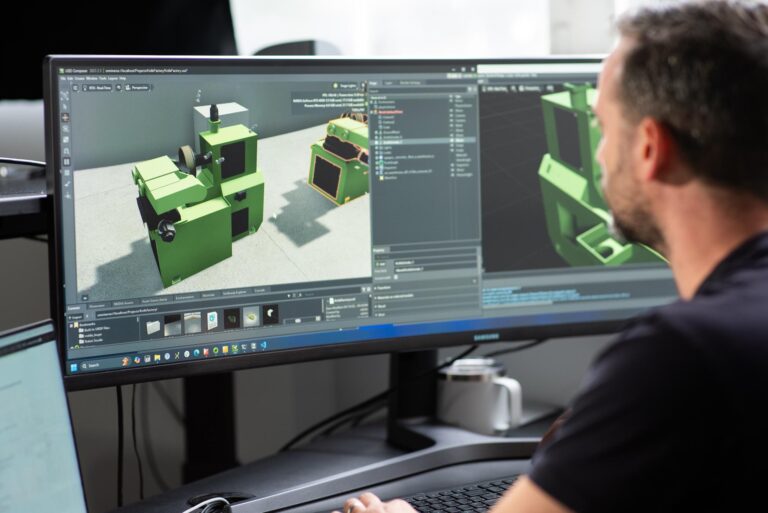

Using digital twin technology, we were also able to simulate and validate the system early in the process. This allowed the team to accurately calculate the robot’s movements and tension requirements without needing to rely solely on physical testing. Also, by leveraging Loupe’s existing infrastructure, the project bypassed initial setup phases, enabling rapid progress directly into process development.

THE RESULT

From Concept to Funding

In just a single, six-week sprint, we delivered a working prototype that exceeded expectations — enabling the company to secure additional funding and grow their team.

“Rapid prototyping with limited in-house resources is our specialty. This collaboration was a natural fit, and we’re proud to be a part of their success.”

Josh Polansky, Technical Fellow, Ship in Six

This technological breakthrough sets the stage for continued innovation in construction automation, and we’re glad to have been a key partner in their journey from concept to prototype.