Pushing the Limits of Carbon Fiber Technology

In this Ship in Six case study, learn how we helped Fives Machining Systems develop a groundbreaking carbon fiber printer — achieving unprecedented precision and speed in aerospace manufacturing through advanced software and hardware integration.

When it comes to aerospace manufacturing, precision and speed are paramount. A global leader in industrial engineering, Fives Machining Systems has long been at the forefront of machine design and process equipment for the aerospace industry. Together, we embarked on a groundbreaking project to develop an innovative carbon fiber printer aimed at enhancing capabilities for their aerospace clients.

THE CHALLENGE

Meeting Aerospace’s Exacting Standards

The machine features a large head that applies carbon fiber tape strings, which required tracking onto surfaces with the utmost precision. This complex system involved a mandrel, a robot, and a rail, all working in unison.

The primary challenge? Ensuring the machine’s actuator timing was spot-on (despite the inherent delay in cutting the bands) and the need to predict precisely when and where cuts would occur. Key constraints included:

- High Speed: The printer needed to operate at speeds of up to a meter per second.

- High Accuracy: It also needed to achieve fiber placement accuracy within 0.2mm, a feat beyond the capabilities of most off-the-shelf robots (which average ~5mm).

- Actuator Timing: With a cutting mechanism that required precise timing (2/10 of a second) to ensure accurate fiber placement, the system needed to predict cuts with meticulous precision.

THE SOLUTION

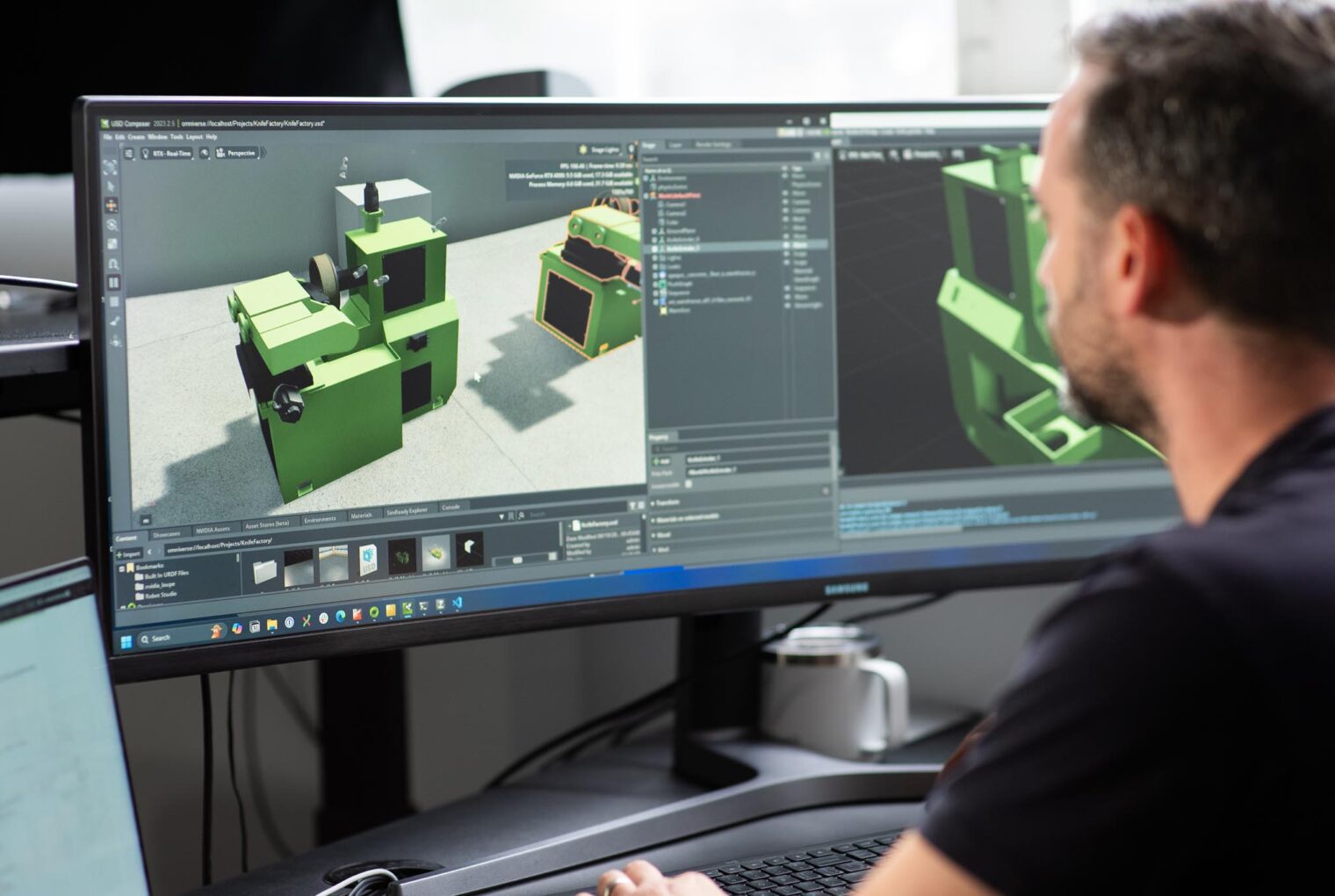

At the Intersection of Hardware and Software

Loupe’s expertise was crucial in addressing two major aspects of this project: developing advanced software for the robot and troubleshooting mechanical issues with the motor system.

First, recognizing that off-the-shelf software solutions couldn’t meet our precision requirements, we developed custom software tailored to the robotics platform. Leveraging B&R’s advanced robot pathways, we integrated real-time modeling to compensate for dynamic factors like gravity and rail imperfections. This was the first machine to incorporate live compensation, moving beyond pre-planned corrections to adjust in real-time. Then, by integrating Synchro Buffer, Loupe’s software anticipated the robot’s path and coordinated actuator operations with remarkable precision, ensuring cuts were made exactly where needed.

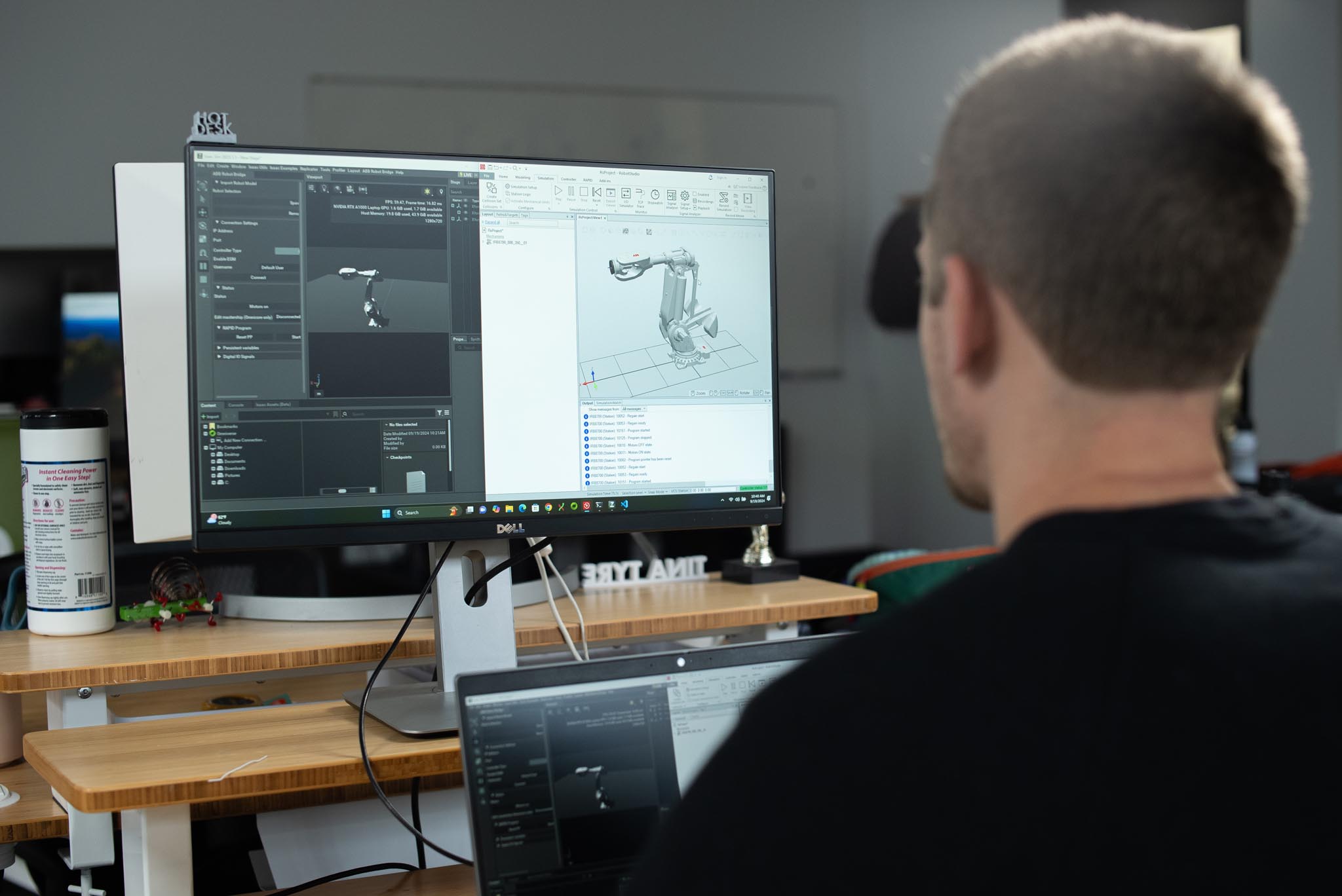

In phase two, we tackled the hardware. With the need for a robust robot to handle the heavy carbon fiber head, Loupe opted for an ABB robot — renowned for its mechanical strength, but initially incompatible with the desired precision. Thus, we undertook the challenging task of reverse-engineering the robot’s drive system, dismantling the motors to meticulously analyze their physical artifacts — measuring windings, determining gear ratios, and parameterizing the drive system to ensure seamless integration.

Other obstacles we overcame:

- Safety Enhancements: Replaced ABB’s resolvers with encoders, allowing the robot to remain powered during operation and enhancing overall safety.

- Encoder Compatibility & Calibration: In addition to adapting encoders to be compatible with B&R drives, we also addressed issues with single-turn encoders and calibration faults.

- Avoiding IP Infringement: Navigated existing patents and achieved similar results through innovative methods without infringing on intellectual property.

“Not many can merge advanced software development with hands-on hardware analysis. Our dual expertise allowed us to address both and deliver a game-changing solution for Fives.”

Josh Polansky

Technical Fellow, Ship in Six

THE RESULT

Unmatched Performance and Accuracy

This new carbon fiber printer has automated tasks that were traditionally performed on gantry systems, delivering faster and more flexible performance:

- Reliability: Over 99.9% cut/add reliability with printing speeds of 1m/sec.

- Accuracy: Maintained +/- 0.2 – 0.5mm end placement throughout the full range of operation, with consistent accuracy regardless of speed.

The successful deployment of this machine stands as a testament to Loupe’s capability to tackle complex R&D challenges — including integrating custom software with mechanical engineering. We’re proud to have delivered a groundbreaking platform for Fives to build upon, advancing the state of carbon fiber printing and setting new standards for aerospace applications.